Safer, Better, Easier is the motto we employ as the overriding goal of our Lean-based Continuous Improvement (CI) programs that we roll out at vineyards, wineries, and farms.

I’ve been thinking of how to explain why this is our motto, what it means and the results it can drive. Then we got this email from a client on how one small component of a broader Lean/CI program was fulfilling this goal, and it says it better than I could. It hits all three components multiple times, and importantly, with overlap of the three goals.

- Safer: “they feel safer”, “lot less accidents”, “lot less…property damage”, “less…wire getting caught in mowers”

- Better: “do more value added work”, “cost savings”, “productivity increase”, “cleaner”

- Easier: “eliminating…no-value added work”, “lot less accidents”, “less…wire getting caught in mowers”

But enough from me; let them explain it in their own words:

“Good morning,

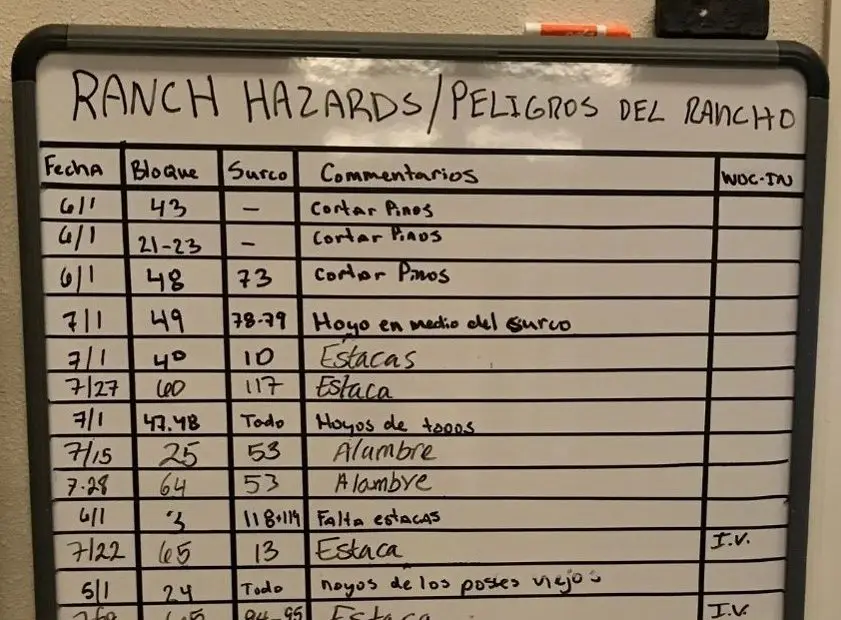

We have received some great feedback from the Vineyard Team’s Operators in regards to the Lean Hazard Board. The Operators have communicated to the management team and myself that they feel Safer and feel the vineyards are a lot cleaner pertaining to broken stakes, broken/ loose wires and broken end posts. We have seen a lot less accidents and property damage in regards to broken doors, broken windows or wire getting caught up in the mowers thus eliminating wasted time. This allows the mechanics and operators to add value to other areas of work within the vineyard.

For reference, before the Lean Hazard Board, we would need four full time employees working almost year round on fixing hazard items (stakes, wires and posts). With the Lean Hazard Board in action, the workers are able to take ownership communicating the hazard and noting them on the board. Management then either weekly or biweekly creates a work order to fix and mitigate all hazards on the board utilizing usually one employee and sometimes two. With this system we are able now to use only two employees for about 2 months to fix the hazard items resulting in a cost savings pertaining to Trellis Repair. We have also seen productivity increase with all cultural activities.

In Summary the Lean Hazard Board has helped with:

- Eliminating waste – non-value added work…

- That results in a cost savings and…

- Frees people up to do more value added work and…

- Makes for a SAFER work place!”

If you’d like to see how we can help you make your vineyard/farming or winery operations Safer, Better and Easier, contact us and let’s see how we can help you.